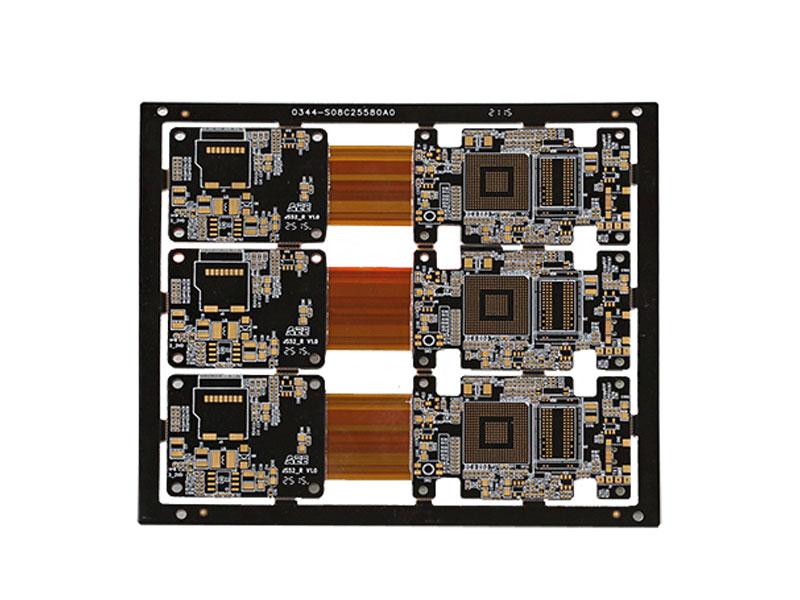

Rigid-Flex PCB

Product Description

ZF Electronics, as one of the top circuit board supplier in China, can provide customers with single-sided PCB, double-sided FR4 PCB, metal core PCB, heavy copper PCB, rigid PCB and rigid-flex PCB. It provide pcb board, single layer pcb, multi layer board, rigid flex pcb, aluminum pcb,etc.

PCB Rigid flex is a new type of PCB that combines the durability of rigid PCB and the adaptability of flexible PCB. Among all types of PCBs, this combination is the best to deal with harsh application environments with high resistance. Therefore, it is favored by industrial control, medical, and military equipment manufacturers while many enterprises are also gradually increasing the proportion of rigid-flex PCB in total output.

Classification of rigid-flex PCB

According to the manufacturing process, the method of combining the rigid flex printed circuit boards and the flexible board can be divided into two types of products, the rigid-flex clad plate and the rigid-flex PCB. The difference of the two lies in the technology of the rigid-flex PCB, which can combine the rigid board and the flexible board during the manufacturing process. Among them, the blind via and buried via design can be commonly achieved to create a higher density circuit design. The technology of rigid-flex PCB is to make the rigid board and flexible board separately and then press them into a single board with signal connection but no through-via design. But at present, the name "rigid-flex PCB" is commonly used to refer to all rigid and flexible combined board products without subdivision.

Physical characteristics of the rigid-flex PCB

The rigid-flex PCB is different from the previous flexible PCB and rigid PCB in terms of materials, equipment and manufacturing process.

As for materials, the material used in the rigid board is material such as FR4, and that of the flexible board is PI or PET, which may cause problems such as bonding and different heat shrinkage rates, making the products unstable. However, the rigid-flex PCB boasts the three-dimensional spatial configuration, so that the stress in not only the X and Y-axis directions but also Z axis direction should be taken into consideration. At present, some material suppliers will provide PCB manufacturers improved materials suitable for the rigid-flex PCB, such as epoxy or resin, to meet the bonding problems between the rigid PCB and the flexible PCB.

The equipment in the pressing and copper plating parts of rigid-flex PCB must be corrected due to the differences in material characteristics and product specifications, or the product yield and stability will be affected. Therefore, the suitability of the equipment must be taken into consideration before the production of the rigid-flex PCB.

Basic process flow of rigid-flex PCB

(1) Material selection

(2) Quality control of production process and key steps

①Production process

②Pattern transfer of single-chip in inner layer

③Multi-layer positioning of flexible materials

④Lamination

⑤Drilling

⑥Desmear and remove pitting

⑦Chemical copper plating, electrocoppering

⑧Surface solder resistance and solderability preservative

⑨Shape processing

Advantages of rigid-flex PCB

(1) The advantages of rigid-flex PCB over general PCB:

① Light weight

② Thin interlayer

③ Short transmission path

④ Small via aperture

⑤ Less noise and high reliability

(2) The advantages of rigid-flex PCB over rigid PCB

① Flexible and can be wired in three dimensions to change shape according to space constraints

② High and low-temperature resistance and flame resistance

③ Foldable without affecting the signal transmission

④ Prevent electrostatic interference

⑤ Stable chemical changes, excellent stability and high reliability

⑥ Conducive to the design of related products, which can reduce assembly man-hours and errors and increase the service life of related products

⑦ It can reduce not only the size of the application product, but also weight significantly, as well as cost, and the functions are increased

If you have questions about our rigid-flex PCB production capacity, or the specifications required for your custom project are not listed on this page, please feel free to contact us. We will reply within one workday. We will continue to provide quotation support and design support. Welcome to learn about our production process.

This rigid flex pcb factory offer rigid flex pcb fabrication, and the rigid flex pcb price is very cheap, because of rigid flex pcb cost.